True Green Cities/Celebrating Thirteen Years: Revisiting a Historic Factory

Celebrating Thirteen Years! It’s been thirteen years since I launched Barbara A. Campagna/Architecture + Planning, PLLC on April 19th, 2011 and while many things have changed, my goal to work on “greening what’s already here” continues to be met, often in places I never expected.

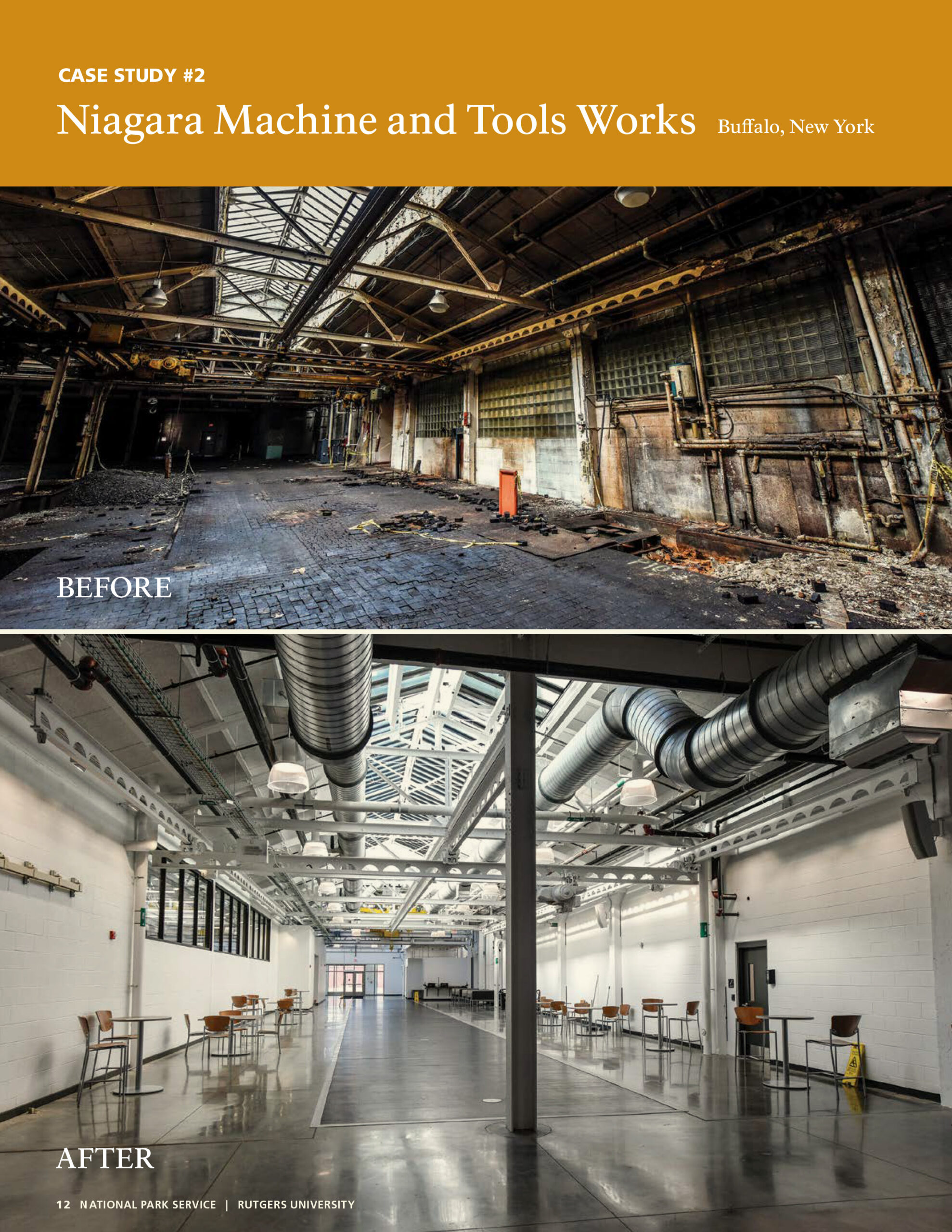

Niagara Machine & Tool Works Factory

The Niagara Machine & Tool Works Factory was rehabilitated from 2016-2020 into a neighborhood-changing workforce training center. I had the privilege of being the preservation architect on the team led by prime Watts Architects & Engineers. It is a successful project from a preservation aspect, a social justice aspect and a community enrichment aspect. The historic factory was listed on the National Register of Historic Places as a historic district with three contributing buildings. Two of the buildings were rehabilitated in this first project, and the third building’s remaking has just been begun. It’s thrilling and rewarding to be the preservation architect for this third building also, completing the renovation of the district.

The third building, the 1953 Metals Fabricating Plant, is being studied and renovated by prime Wendel with my firm as the preservation architect. This 35,000-square foot rectangular industrial factory building is sited on a separate parcel on the south side of Northland Avenue between Winchester and Longview avenues. It is adjacent to the Belt Line railroad corridor and stands to the west of the Main Factory. The building was formerly used for heavy manufacturing and recently to store former industrial equipment. The building was designed by H. E. Plumer & Associates and has an International Style aesthetic with a steel-frame on a concrete foundation, a brick veneer and bands of ribbon windows. The factory’s growth demonstrated the advancements of the twentieth century factory and exhibits many of the original character defining features which explain the manufacturing process such as the height, breadth and open volume of the factory spaces. The 10 to 50-foot high assembling spaces indicated the large pieces of equipment that were assembled in the space. We look forward to sharing our progress next year!

Northland Central/Northland Workforce Training Center

The Northland Workforce Training Center has been lauded by many organizations including the National Park Service who featured it in their annual Tax Credit report in 2021. Below is the information on the completed project that we were honored to share with the country.

Historic Name: Niagara Machine & Tool Works Factory

Year Built: 1910-1967

Rehabilitation Completed: 2019

Original Use: Factory and Company Headquarters

New Use: Workforce Training Center and related light industrial space

Total Project Cost: $111,702,975.00

Estimated Qualified Rehabilitation Expenditures: $92,958,078

History & Context

Northland Central occupies the former Niagara Machine & Tool Works Factory on Buffalo’s East Side. The complex is an intact representative example of a large-scale tool and machine factory designed and built during the first half of the twentieth century. The company played an important role in defense contracting for World War I and World War II, as well as in the development of the East Side of Buffalo along the Belt Line railroad. Noted Buffalo architectural firm Green & Wicks designed the original buildings, with additions from local civil engineers. The complex includes an exposed reinforced-concrete-framed, four-story office building and manufacturing spaces constructed of concrete, brick and steel with steel-framed sawtooth and monitor skylights. Most of the company’s manufacturing activities ceased at the site by 1999. It was purchased by a City of Buffalo development agency from the private owner in 2015.

Scope of Work

The Niagara Machine and Tool Works Factory Complex National Register-listed Historic District consists of three distinct buildings related to specific functions of the manufacturing facility and the factory’s evolution. Although the buildings had been deteriorating for decades, they were mostly intact. All exterior concrete and brick walls and ornament were restored. Hazardous materials abatement included replacement of all existing doors, windows, skylights, and monitors. The new aluminum windows were designed to match the original steel as closely as possible. The interior factory space was partitioned to use the space practically, but vision windows were installed along the walls between laboratory spaces to provide a visual continuation reminiscent of the former factory floor. To comply with current energy codes, interior insulation was added to the uninsulated exterior masonry walls, and existing walls were exposed where possible. The factory building was structurally sound but required some retrofits to meet current snow loads required by code. An original entrance along the front elevation was restored as the main lobby public entrance.

Role of the Historic Tax Credit

All financing sources were essential to reuse the complex. Other important incentives included the New York State Historic Tax Credits, Federal New Market Tax Credits, Brownfield Tax Credits, New York Power Authority grants and “Buffalo Billion” grants.

Impact to the Community

Northland Central represents a revival in an industrial neighborhood that was once considered forgotten by its residents. Its reuse as an energy and manufacturing educational center maintains the industrial significance and aesthetics of the complex. The project was the first step in the revitalization and reuse of one of Buffalo’s great historic factory districts. Since this rehabilitation, two other factory buildings have been reused and infill housing is planned.

The project also received LEED Silver, restoring many historic features which contributed to the sustainability of the site including the reactivation of all the sawtooth monitors, clerestories and skylights providing daylight throughout the complex (see “after” photo below).

Thank you to all my clients, consultants and colleagues who have supported Barbara A. Campagna/Architecture + Planning, PLLC.